Boxed Packaged Goods: 9 Types of Packaging, Uses & Filler Materials

Learn the different types of box packaging and uses for your business.

December 9, 2023

December 9, 2023 8 minute reading

8 minute reading

When you want to step up your branding to stand out while creating a strong customer experience, boxed packaged goods should be a priority.

Packaging makes an enormous impact on how customers perceive your brand. Everything from the colors, materials, and designs you use can impact what customers think of your brand and affect how you stand out against the competition. Taking the time to have custom packaging created for your brand is an extra step that can go a long way for the success of your business and solidifying the recognizable brand that you're working hard to build.

In this guide, we go over everything you need to know about the different types of packaging boxes and filler materials you need to consider to successfully protect the inner goods during shipping.

Boxed packaged goods guide - Types of packaging, uses & filler materials

1. What are boxed packaged goods?

Boxed packaged goods are simply goods that have been packed in a box.

The packaging helps preserve the item during shipping while also creating a strong branded experience even once it arrives to the customer. These boxes can come in a variety of shapes and sizes in addition to different materials. Some types of packaging will encase a product directly and be included on display shelves (like the product box containing food), while others will be designed exclusively for shipping or transit (like cardboard boxes to ship to consumers).

2. Difference between primary, secondary & tertiary types of packaging

It's essential to know the difference between these two types of packaging because each will be used for different products and different purposes; they're not all going to suit every type of consumer or business. Having the proper options for each will ensure that the customer experience is strong, your branding is enhanced, and your products are fully protected.

Let's take a look at each type of packaging and the differences between them.

Primary packaging

Primary packaging — which is also sometimes called "consumer packaging" or "retail packaging" — is the packaging in direct contact with the product itself.

For a soda, the primary packaging is the aluminum can or glass bottle it comes in. For cosmetics like lipstick or mascara, it would be the plastic casing around the makeup.

Primary packaging design typically incorporates your business' logo, branded colors, tagline, and marketing copy on the outside and potentially even on the insight. It helps to establish brand awareness and name-brand recognition, and it's also designed to help you stand out on the shelves when users are browsing. Great packaging can also help grab user attention online and establish brand loyalty.

Retail packaging is essential when it comes to differentiating your brand from your competition, even if your products are otherwise similar. It makes a direct impression on potential customers, so it's crucial to have strong, well-branded designs for this level of packaging.

As a result, retail packaging is going to be the most important packaging decision that you'll make. It's like your ultra-visible secret weapon, as it can and does directly impact buyer behavior. Making this packaging choice first (and making it carefully), is a good way to go. It can be worth the investment.

Keep in mind, too, that retail packaging offers all of the following benefits:

It's 100% customizable, so you can make it look like whatever you choose

It can help you to attract new customers

In many cases, it may be a customer's gateway path to your brand

Strong branded packaging increases the perceived brand value (which means, in turn, that customers may buy more often or be willing to spend more)

Common types of retail packaging

There are several common types of retail packaging that eCommerce brands typically use. These include the following:

Rigid packaging: made from solid materials that hold their shape well. Examples may include plastic bottles for liquid, glass or plastic bottles, cardboard boxes, and plastic lining like you'd see in a cereal box. These are often used for food, electronics, toys, and household cleaners.

Flexible packaging: a number of different materials are used to create flexible packaging, which typically loses its shape once the packaging is opened. These packages are air-tight before opening and are often made from plastic bags. As a result, they're typically used for perishable food products (including bags of chips and pet food). Some are resealable after opening; some are not.

Recycled packaging: an extremely popular type of packaging because it's so eco-friendly. It utilizes recycled plastic, glass, or paper from past discarded items to create new packaging. It may be more cost-effective, and the fact that it's a green solution can go a long way to appealing to customers who care about environmental friendliness.

Custom packaging: designed for products with uncommon or irregular shapes that may be difficult to fit in conventional packaging. It can also include packaging designed specifically for certain businesses, containing branded designs to help them stand out and ensure that the products are secured in packaging made to keep them safe. Custom boxes may be more expensive and can come in any of the forms we've described so far.

Secondary packaging

Secondary packaging, which is also known as a stock-keeping unit (SKU), is used outside of primary packaging to group a select number of items together. This is often used for smaller products, collecting them in single packs. It is, in other words, the packaging used to ship products that are already in primary packaging or to create "bundles" of an item in primary packaging. It's often made of printed cardboard with distinct branding, though this isn't always the case.

Secondary packaging can help protect the primary packaging and the products, allow shipping centers to manage products more easily when distributing them to retailers, and allow brands to sell bundled items. An example would be a 12-pack of sodas, which has primary packaging of aluminum cans and secondary packaging of plastic wrapping or cardboard boxes grouping them together.

In many cases, secondary packaging is made up of multiple components designed to protect the product. This might include an outer box or plastic layer, padding, inserts, separators, bags, reinforcements, and more.

Secondary packaging is protective during shipping, and it can also provide enhanced branding to help you stand out. When it's used to group similar items together (like a 12-pack of soda), it may be referred to as "group packaging" or "display packaging." It's retail- and shelf-ready, and it can include counter-top display units (CDUs). It normally plays a crucial role in the marketing funnel, unboxing experience, customer perception, and buying decisions.

Mailer boxes are a popular type of secondary packaging because they’re sustainable and use less packaging supplies to send smaller goods. They’re a great option for subscription and gift boxes.

Tertiary packaging

Tertiary packaging is also known as "transit" packaging or "bulk" packaging.

It's used to group large quantities of a single SKU to transport them from location A to location B, like a production facility to a wholesaler or retailer.

This packaging is used to handle groups of products as distribution units to make organization and distribution much more streamlined. As a result, this is often heavy-duty packaging that makes it possible to easily and securely transport heavy and/or large loads from place to place, alongside storing it once it arrives.

An example of tertiary packaging would be stretch-wrapped pallets containing multiple storage boxes that contain individually packaged products. The tertiary packaging (pallets) contains the secondary packaging (cardboard boxes) which contains the primary packaging (rigid boxes containing the products).

This is most often used by production companies and warehouses as shipping boxes for secondary packaging, and it's almost never seen by consumers.

3. Types of packaging boxes and uses

Corrugated boxes

Corrugated boxes are made from corrugated board, which is three layers of thick paperboard sheets. The two outer sheets are flat, and the paperboard sheet in the middle has a rippled shape. The three sheets are glued together with starchy, thick glue that creates a strong and heavy-duty box.

Corrugated cardboard boxes are made from corrugated board, which is three layers of thick paperboard sheets. The two outer sheets are flat, and the paperboard sheet in the middle has a rippled shape. The three sheets are glued together with starchy, thick glue that creates a strong and heavy-duty box.

The pros of corrugated boxes include:

Undeniable strength, which helps keep products safe during handling and distribution when used as outer packaging

It's often used to safely transport a large variety of products, ranging from household electronics, food items, cosmetics, and more

While it isn't waterproof, it does offer strong moisture protection to help keep the items inside moisture-free

They're lightweight, easy to store, and easy to handle

These boxes are cost-effective and easy to manufacture

They are simple to customize, allowing for strong branding opportunities and making it possible to use them as display boxes in some cases

They're easy to recycle, making them eco-friendly

No packaging solution is perfect for every brand, however, and there are some drawbacks to corrugated boxes. The only significant con here is that corrugated cardboard doesn't have a particularly high-end look. For couture or luxury items, customers may expect more high-end packaging options like wooden or rigid boxes for their product packaging.

Cardboard boxes

Cardboard boxes are made out of layers of heavy paper. They're one of the most common types of packaging, and they typically consist of a single layer of cardboard. Shipped flat to save space, they're printed and cut so that they can be put together with flaps or folding panels.

Cardboard boxes are made out of layers of heavy paper. They're one of the most common types of packaging, and they typically consist of a single layer of cardboard. Cardboard boxes can also be made out of Kraft, a material more durable thann standard cardboard. Shipped flat to save space, they're printed and cut so that they can be put together with flaps or folding panels.

In many cases; these are called folding cartons, and they're typically secured with tape, though sometimes starchy glue is used.

These are the biggest advantages of cardboard boxes:

They're highly flexible and customizable

They can be shipped and stored flat, and structured as needed

They're extremely lightweight

You can print just about anything you'd want on it

You can create a high-end and even glossy finish for appealing retail packaging

It's highly recyclable

It's a good option for primary packaging for all kinds of products, and it may increase shelf life and product protection

While cardboard boxes do have some significant benefits, there are also some cons to consider. These include the following:

It may not be a good fit for extremely heavy items, like weight sets

There may be a lack of structural integrity when stacked with products inside; depending on the weight of the boxes and the type of cardboard, they can be warped if heavy items are stacked on top, which can be a problem for product storage with primary packaging

Cardboard will easily be deformed once exposed to water, and it may not be able to protect the products inside

Wooden boxes

Wooden boxes aren't the most common packaging type, but they're still used in niche situations. Packaging professionals in the moving industry often use wooden boxes to transport items, and delicate products (like a painting) may be shipped across long distances in wood packaging to offer the most secure protection possible.

Wooden boxes aren't the most common packaging type, but they're still used in niche situations. Packaging professionals in the moving industry often use wooden boxes to transport items, and delicate products (like a painting) may be shipped across long distances in wood packaging to offer the most secure protection possible.

These are the biggest advantages of wooden boxes and crates:

They're extremely safe and sturdy; wooden boxes may actually be the best candidates to ship fragile products safely to minimize the risk of damage

Wooden boxes maintain their integrity in all kinds of weather and can protect the items inside

You can stack many boxes on top of each other without damage

They're particularly valuable when it comes to shipping items long distance

Let's take a look at the cons of wooden boxes as a packaging solution:

Custom wooden boxes can be incredibly expensive, so they're often not a cost-effective choice when there are other options available for your products and your business

Wood can become moldy if it isn't treated properly; this can lead to significant product damage in some cases and result in a poor customer experience

Chipboard packaging

Chipboard is a cardboard-like material that's lightweight and versatile. You can create packaging boxes for all kinds of products, as it comes in a wide variety of wall thicknesses ranging from 10 pts to 100+ pts. That said, it is the weakest of the packaging types even on the strong end of the spectrum.

Chipboard is a cardboard-like material that's lightweight and versatile. You can create packaging boxes for all kinds of products, as it comes in a wide variety of wall thicknesses ranging from 10 pts to 100+ pts. That said, it is the weakest of the packaging types even on the strong end of the spectrum.

This makes it a better choice for display purposes in retail as primary or secondary packaging for lightweight products or in POP applications than for long-term product storage or transport. It's often used for items like toothpaste packaging, medicine packaging, or small cosmetics packaging.

These are the most significant pros of chipboard packaging:

It's inexpensive, making it a cost-effective option when it works for your products

It's easy to print on, allowing for custom branding

It's extremely lightweight

The material is incredibly recyclable, making it a more eco-friendly choice

Direct printing chipboard is a great surface for high-quality graphics and even photographs to be printed on

There are two disadvantages to chipboard packaging:

The packaging is not water-resistant at all, so it should never be used for shipping

The packaging isn't strong enough to withstand the kind of damage that happens in shipping, meaning it should only be used for primary packaging

Rigid boxes

Rigid boxes are made from paperboard that's highly condensed and around 4x thicker than your standard folding cardboard carton. They have a glossy and high-end finish that can be printed on, making them a popular choice for electronics.

Rigid boxes are made from paperboard that's highly condensed and around 4x thicker than your standard folding cardboard carton. They have a glossy and high-end finish that can be printed on, making them a popular choice for electronics.

This is why you often see rigid boxes used as primary packaging for items like an iPhone or a new gaming console. While rigid boxes are outstanding for primary packaging, they need secondary packaging for shipment.

These are the benefits of rigid boxes as a packaging option:

They have a high-end, premium look and feel that works well for high-end products, including electronics

They're easy to customize and work well for gorgeous printing

They're non-collapsible, meaning they're structurally fairly strong

You can make rigid boxes that are biodegradable for an eco-friendly option

There are also some negatives to consider. These are the cons of rigid boxes for packaging:

They're expensive and rarely cost-effective compared to other options

They're often considered part of the product experience, so they need to have secondary packaging protecting it

Foil-sealed bags

Foil-sealed bags are more durable than most plastic or paper bags and are often used for packaging small items. They're most commonly used for food, but they also work to transfer and sell electronics as they're anti-static and will keep moisture out.

Foil-sealed bags are more durable than most plastic or paper bags and are often used for packaging small items. They're most commonly used for food, but they also work to transfer and sell electronics as they're anti-static and will keep moisture out.

As a result, they're typically used as primary packaging, though they may sometimes be used as secondary packaging.

These are the many significant advantages of foil-sealed bags as a packaging option:

They're anti-static and soft, and the thickness can be adjusted freely depending on your product needs

They're suitable for both food and electronics, including electric components like a circuit board

Can be used as primary or secondary packaging

They can be printed with custom branding

They're vacuum-sealed, meaning there's complete protection from moisture, dust, mold, or any other sources of contamination that could damage the products

There are cons of foil-sealed bags, which include:

They aren't recyclable, so they aren't eco-friendly

They can't be used as standalone packaging, and at minimum, a layer of paperboard boxes will be needed for transport and potentially storage

The packaging doesn't offer protection against dropping, crushing, or other physical damage

Poly bags

Poly bags are essentially plastic bags, which can carry a wide variety of different products. They're typically very small and thin and may be used for products like small electronic components, loose gemstones, and more.

Poly bags are essentially plastic bags, which can carry a wide variety of different products. They're typically very small and thin and may be used for products like small electronic components, loose gemstones, and more.

These are the biggest advantages of using poly bags as primary packaging:

They're more durable, flexible, and lightweight than boxes

They're reusable, and can often be reused many times

It's easy to create them with custom designs and sizes

They're cost-effective, and they can be recycled

While these advantages are great, you'll want to keep the following cons of poly bags in mind:

The packaging doesn't protect against dropping, crushing, or other physical damage

The reality is that while they can be recyclable, most poly bags are small and never make it to a recycling plant; in some areas, they may not be accepted for recycling

You'll need at least one box as outer secondary packaging

Woven bags

Woven bags can be made from several different materials, but are most frequently made out of cotton or polypropylene. They're typically used by environmentally-focused brands when possible. Woven bags work well for products like a bottle of perfume, wrapping around a bouquet instead of plastic wrap, or clothing.

Woven bags can be made from several different materials, but are most frequently made out of cotton or polypropylene. They're typically used by environmentally-focused brands when possible. Woven bags work well for products like a bottle of perfume, wrapping around a bouquet instead of plastic wrap, or clothing.

It wouldn't work, however, for electronics or most food items aside from fruits or vegetables. Keep in mind that these materials can have fibers that come loose, so they shouldn't be used for any products where those fibers could damage the products.

These are the benefits of using woven bags:

They're eco-friendly and allow brands to have a "green" appeal to customers

They're much more recyclable and reusable than other packaging options

They're easy to customize

They have a high-end look and feel, especially since green products are popular

There's really one significant downside to using woven bags as a packaging option, and it's that they offer very little protection of any kind, including against damage like dropping and crushing or against moistur

Plastic box packaging

Plastic box packaging has risen to popularity since the 1950s and is often created from high-density polyethylene. Plastics are commonly used but, due to the fact that they aren't eco-friendly to produce or discard, they're becoming slightly less popular for some products.

Plastic box packaging has risen to popularity since the 1950s and is often created from high-density polyethylene. Plastics are commonly used but, due to the fact that they aren't eco-friendly to produce or discard, they're becoming slightly less popular for some products.

These are the benefits of plastic packaging:

It's low cost to produce and is often the cheapest out of the common packaging materials

It has strong durability, withstanding falls or bangs

Plastic is long-lasting and waterproof, meaning it offers good protection

It's lightweight, making it easy to handle and reducing shipping costs

It offers strong versatility and can be made into different shapes and sizes

These are the cons to consider:

There's a large carbon footprint, often using fossil fuels to produce while creating high amounts of carbon dioxide

Most plastic isn't properly recyclable, with over 91% of plastic in the world going to landfills instead of being recycled

There's a major focus amongst a large number of consumers to be more "eco-friendly" and they may look for plastic-free alternatives

Paper box packaging

Paper box packaging is paper-based packaging that's lightweight, eco-friendly, and often used for primary packaging. It's long been an extremely popular packaging option, but it's become more popular in recent years.

Paper box packaging is paper-based packaging that's lightweight, eco-friendly, and often used for primary packaging. It's long been an extremely popular packaging option, but it's become more popular in recent years.

These are the benefits of paper box packaging:

It's biodegradable

It's made from wood, which is sustainable

It's versatile and can be printed directly on

It's popular with consumers and brands who care about eco-friendliness (which a large percentage do)

There are a few disadvantages to consider, which include the following:

It doesn't have as strong of barrier properties as other options, meaning that oxygen, light, and other environmental factors may damage the product

It often ends up in landfills even though it's reusable or recyclable; since some landfills lack oxygen, it may resist the breakdown process

Paper box packaging often takes up more space than the same weight of plastic in landfills since it's less dense

4. Types of packaging filler materials

Let's take a look at the most popular types of packaging filler materials used to protect and buffer a product from potential harm or destruction during shipping or warehousing.

Packing peanuts

Packing peanuts are small pieces of material — often made from Styrofoam— that can be shaped like peanuts, small rectangles, or other custom designs. They're put inside boxes to provide cushioning to the product and to keep it stationary instead of the packaging so it isn't rattling around.

Packing peanuts are small pieces of material — often made from Styrofoam— that can be shaped like peanuts, small rectangles, or other custom designs. They're put inside boxes to provide cushioning to the product, like bubble wrap, and to keep it stationary instead of the packaging so it isn't rattling around.

These are the benefits of packing peanuts:

They're cost-effective and good for protecting fragile items during shipment and transit.

The downside to packing peanuts is that they're not recyclable if they're made of Styrofoam, though there are other types of packing peanuts available that may be recyclable or biodegradable.

Mushroom mycelium and hemp

Plenty of companies are working on offering biodegradable and eco-friendly packing materials. One company, Mushroom® Packaging, for example, is developing packing materials made from only the two ingredients of hemp hurds and mycelium.

Plenty of companies are working on offering biodegradable and eco-friendly packing materials. One company, Mushroom® Packaging, for example, is developing packing materials made from only the two ingredients of hemp hurds and mycelium.

These packing materials are cost-competitive and can be both water-resistant and offer thermal insulating benefits, all while still being able to compost within 45 days.

The downside here is that costs can be more expensive compared to packing peanuts in many cases, which may be a barrier to access for small businesses on a tight budget at this time.

Green cell foam

Green cell foam is growing in popularity, and it's another sustainable packing material. It's a great option for food products because there's no risk of contamination from the packaging as it's non-toxic, but it can work well to protect almost anything that you need to secure during transit.

Green cell foam is growing in popularity, and it's another sustainable packing material. It's a great option for food products because there's no risk of contamination from the packaging as it's non-toxic, but it can work well to protect almost anything that you need to secure during transit.

While green cell foam is not a recyclable material, you can compost it or rinse it down the drain. Since it's compostable, it's safe to discard, so you know that you won't be contributing to long-term landfill waste.

Geami

Geami is made from craft paper and tissue paper, and it's recyclable. You can quickly wrap products without any need for tape, giving you an incredibly eco-friendly option. For companies truly invested in sustainability, this is an excellent option to reduce as much plastic as possible.

Geami is made from craft paper and tissue paper, and it's recyclable. You can quickly wrap products without any need for tape, giving you an incredibly eco-friendly option. For companies truly invested in sustainability, this is an excellent option to reduce as much plastic as possible.

Molded pups

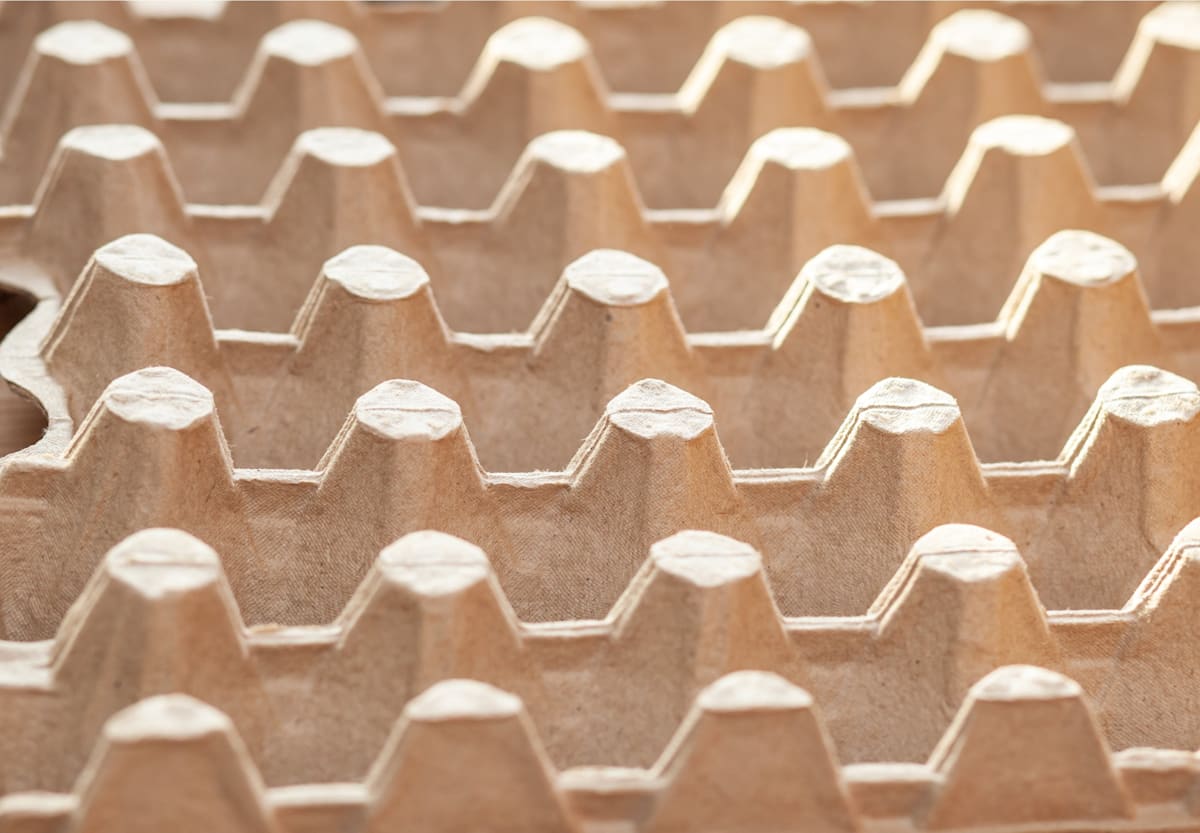

Molded pups are also known as "egg packaging," and they're made from recycled water and paper. They may resemble small cartons, and you can use them to secure items inside their primary packaging. They can be customized to fit your specific products for the most secure fit.

Molded pups are also known as "egg packaging," and they're made from recycled water and paper. They may resemble small cartons, and you can use them to secure items inside their primary packaging. They can be customized to fit your specific products for the most secure fit.

In some cases, they may also appear as primary packaging, like in use as an egg carton or to package electronics.

The bottom line

Whether you're an eCommerce company distributing your products online or a manufacturer sending your goods off to retailers or wholesalers, boxed packaged goods can get damaged during shipping, however by choosing the right type of packaging box and filler material you can deliver perfectly packaged goods to your customers while creating a high-level customer experience.